HOW TO MAKE IT APRIL 8 2022

by Design Miami

MASS and HYDRO, Tom Dixon’s latest innovative, beautifully built-to-last collections

TOM DIXON/ THE MASS TABLE

Photo © Tom Dixon

While the world may have slowed for some over the last few years, British designer Tom Dixon has been as busy as ever, launching multiple collections in rapid succession. For our How to Make It column, we asked him to tell us about two, MASS and HYDRO, both of which bring a bit of tradition into the 21st-century, harnessing material innovations to create enduring future heirlooms.

Dixon unveiled his MASS Table in 2020, composed of modular, highly polished extruded brass “planks.” The form is archetypal, much like a traditional wooden picnic table, but the mirrored golden surfaces elevate the design well beyond the ordinary. The MASS collection also includes a console, a bookshelf, and a coat stand—all made-to-order in the UK to be substantial and long lasting for generations to come.

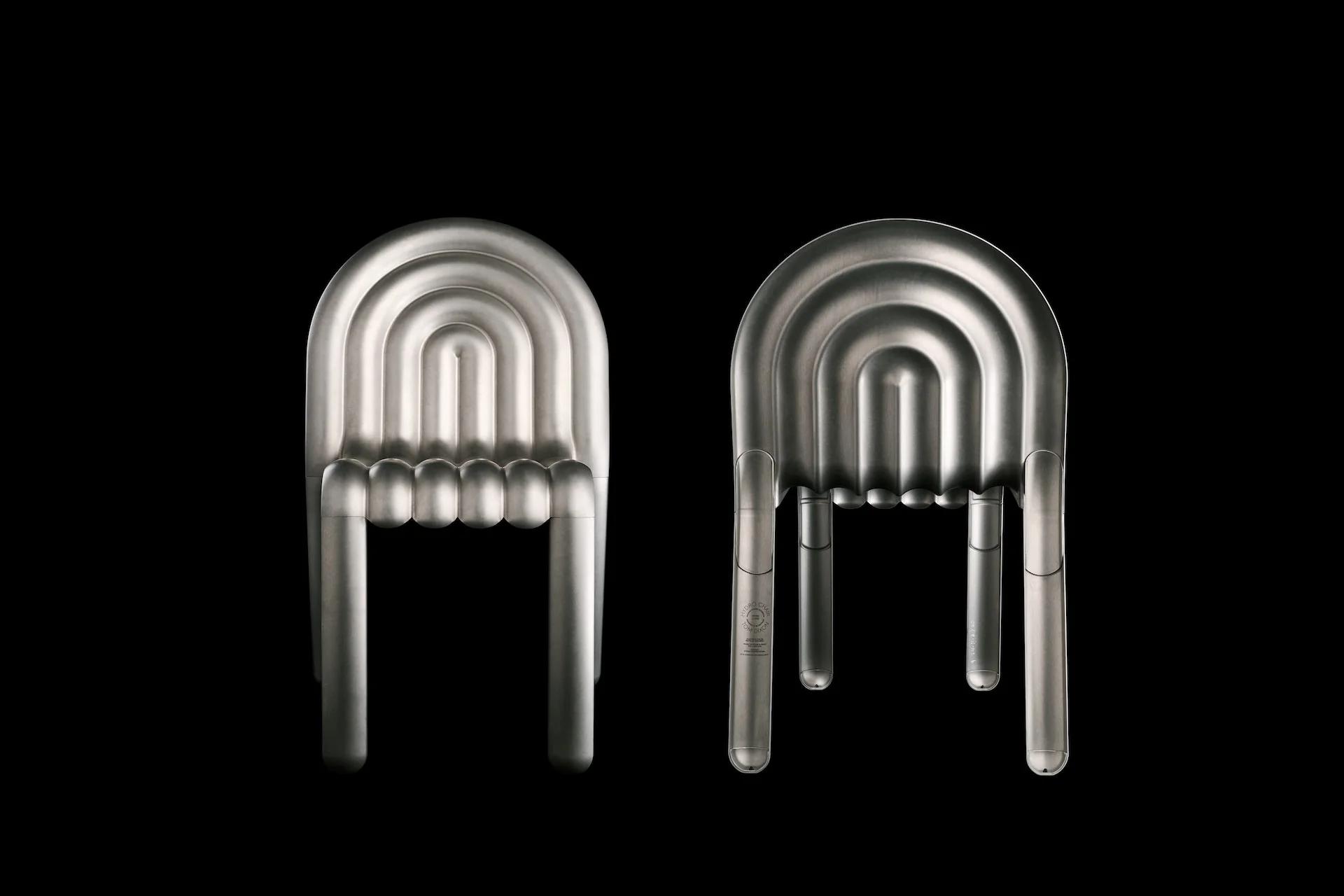

TOM DIXON/ HYDRO CHAIR

Photo © Tom Dixon

HYDRO, meanwhile, debuted in 2021. For this design, Dixon partnered with Norsk Hydro, a world leader in the production of high-tech aluminum parts for the auto and aerospace industries. The HYDRO Chair represents a clever reinterpretation of the classic aluminum chairs so popular in the modernist era. Its distinct thin, undulating silhouette results from a process called Superplastic Forming, in which aluminum is blow-formed at high temperatures and then laser cut by robots. Aerodynamic, lightweight, stackable, super sturdy, and 100% recyclable, the HYDRO Chair makes functional look fabulous.

Scroll on to hear more about MASS and HYDRO from Dixon himself…

Design Miami/What was the vision behind MASS?

Tom Dixon/We wanted to create a system of construction where we could open up the possibilities to other designers and architects to work within a set of predefined parameters.

DM/Why were you attracted to the archetypal building form of a plank for this collection?

TD/I always loved Meccano and Lego as a kid. The idea that from a few building blocks you can construct a multitude of objects appeals to me. The wood plank is a banal and industrialized form of a beautiful natural material, used as the starting point for endless manmade possibilities—from garden huts to dining tables, outdoor chairs, or even boats. I wanted to highlight this capacity for transition (from basic module to many functions) through the use of a more precious material.

TOM DIXON/ THE MASS COLLECTION

Photos © Tom Dixon

DM/Tell us more about the visual tension between the simple, sculptural forms and the highly polished gold surfaces. What attracted you to this approach?

TD/I love the work of the American minimalist sculptors like Carl Andre and Donald Judd, where the careful arrangement of basic forms produces contemplative sculpture. The rectangular section polished brass tube is still recognisable as an industrial-strength metal component, but highly polished it can also be seen as having the material appeal of gold bullion.

DM/Can you tell us more about where it’s made and the fabricators that have brought the design to life?

TD/We get it made in rural Somerset in the west of England, where there is a metal fabrication workshop that specializes in craft metalwork.

TOM DIXON/ THE MASS COLLECTION

Photos © Tom Dixon

DM/What makes the materials and processes behind this collection so special?

TD/MASS is part of our mission to produce indestructible furnishings. Our hope is that these pieces will last for generations and improve with age. You get it in a highly polished finish, which you can either choose to maintain or allow to patinate and show the marks of usage.

DM/What was the vision behind HYDRO?

TD/We wanted to work in the latest technologies to produce an ultra-light stacking chair.

DM/What was it like working with one of the largest aluminum producers in the world, Hydro, for which the collection is named)?

TD/They might be the second largest! But Hydro is committed to innovation, passionate about collaboration, and keen to share their engineering and research insight. So it was a very positive experience. We learnt huge amounts about the extraordinary functionality of that material.

THE PRODUCTION OF TOM DIXON'S HYDRO CHAIR

Photos © Tom Dixon

DM/Tell us more about the material and production innovations behind the HYDRO collection. What about the design’s recyclability?

TD/We made a difficult object, which was produced in Montreal by an affiliate of Hydro that supplies the aerospace industry and the Tesla car company. The chair makes use of newly available glues that bond modern automobiles along with a demanding process for shaping aluminium called superforming.

TOM DIXON/ HYDRO CHAIR

Photos © Tom Dixon

DM/What future applications do you envision for the process?

TD/It’s a great material for lightweight structures. I would love to make an electric scooter or electric speedboat with it.

DM/Do you wish Americans would say “aluminium”?

TD/No, I love the diversity of accents and language. You can keep on calling it ALOOHMINUM as long as you like! It's what makes it fun to travel. ◆